Buffer Adjustment Procedure

Initial Buffer Check

This procedure only needs to be performed upon initial use of the analyzer or in the transition from buffer adjustment with a pH meter. It should be repeated 1) if there is a change to the deionized water system, 2) when a new batch of Buffer Adjustment Solution is prepared, or 3) if the background offset no longer falls between 20000 and 40000 on Gain 1000.

Timberline no longer recommends adjusting the background of the buffer using a pH meter. Adding a known quantity of the ammonium hydroxide solution based on the Offset DAQ setting on the analyzer is preferred. This simplifies the buffer preparation and eliminates potential contamination from a pH meter.

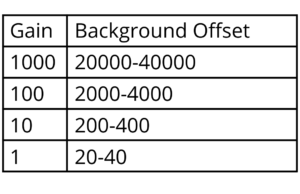

All of the following Steps should be done with a Gain setting of 1000. Once the buffer check is completed, the gain should be set to the appropriate setting for the calibration range. Note that the offset will change with the gain setting.

Contaminated glassware may increase the background offset. Timberline recommends using dedicated reagent bottles.

If using Buffer Stock Solution and Buffer

Adjustment Solution purchased through Timberline:

- Test the DI Water. Place the buffer line in DI water, the caustic line in the caustic solution, and start the pump. When the background has stabilized, zero the cell. The resulting offset should be less than 20000. If it is greater than 20000, a better quality DI water must be used.

- If the DI water offset is less than 20000, prepare a standard buffer solution by diluting 25 mL of the Buffer Stock Solution to 1 L with more of the same DI water tested in Step 1. Place the buffer line in this solution and start the pump. When the background has stabilized, zero the cell. The resulting offset should be less than 25000. If it is greater than 25000, remake the buffer solution. If the problem persists, and the DI water passed in Step 1, check the glassware used to prepare the buffer solution for contamination.

- When Steps 1 and 2 are successful, and there is still nearly 1 L of buffer solution prepared in Step 2 remaining, add 1.5 mL of Buffer Adjustment Solution to the buffer solution. Begin pumping the adjusted buffer solution. When the background has stabilized, zero the cell. The resulting background offset should be between 20000 and 40000 units.

- After passing the initial buffer check outlined in steps 1-3 above, subsequent preparations of buffer solution can be prepared by simply adding 1.5 mL of the Buffer Adjustment Solution to 1 L of DI water containing 25 mL of Buffer Stock Solution. Revisit the procedure outlined in steps 1-3 if the background offset no longer falls within the ranges outlined in the table above.

If preparing Buffer Stock Solution from

boric acid granules and preparing Buffer Adjustment

Solution by diluting ammonium hydroxide solution:

- Test the DI Water. Place the buffer line in DI water, the caustic line in the caustic solution, and start the pump. When the background has stabilized, zero the cell. The resulting offset should be less than 20000. If it is greater than 20000, a better quality DI water must be used.

- If the DI water offset is less than 20000, prepare a standard buffer solution by diluting 25 mL of the Buffer Stock Solution to 1 L with more of the DI water tested in Step 1. Place the buffer line in this solution and start the pump. When the background has stabilized, zero the cell. The offset should be less than 25000. If it is greater than 25000, remake the Buffer Stock Solution and buffer solution. If the problem persists, and the DI water passed in Step 1, check the glassware used to prepare the buffer solution for contamination then change the boric acid reagent being used to a better quality.

- When Steps 1 and 2 are successful, and there is still nearly 1 L of buffer solution prepared in Step 2 remaining, add 0.5 mL of the Buffer Adjustment Solution to the buffer solution. Begin pumping the adjusted buffer solution. When the background has stabilized, zero the cell and check whether the background offset is between 20000 and 40000 units. If the background is less than 20000, add additional Buffer Adjustment Solution, 0.5 mL at a time and zeroing the cell each time after the background has stabilized, until the background offset is between 20000 and 40000. If more than 2 mL needs to be added, remake the ammonium hydroxide solution and repeat Step 3. Note the volume of Buffer Adjustment Solution required to achieve a background of 20000 – 40000. You will use this volume to make subsequent batches of buffer.

- After passing the initial buffer check, subsequent preparations of the buffer solution can be prepared by adding the amount of the Buffer Adjustment Solution determined in Step 3. Revisit the procedure outlined in steps 1-3 if the background offset no longer falls within the ranges outlined in the table above.

Ask Us

We are here for any questions you have